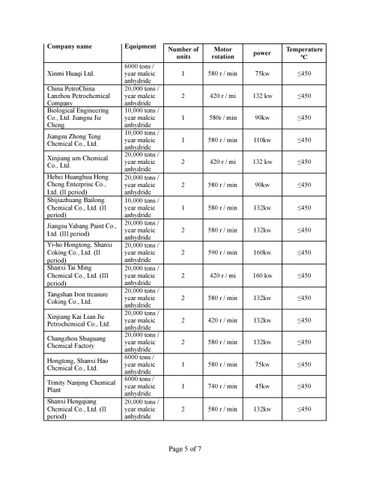

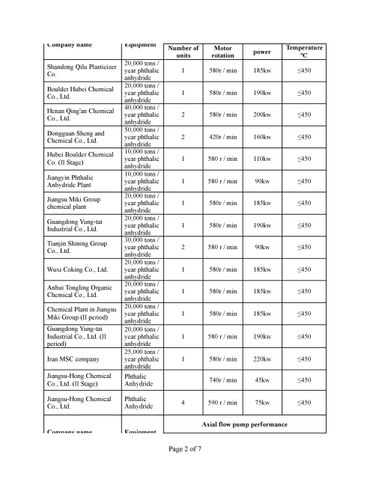

More than hundreds of Axial Flow Pumps in the Market 轴流泵的销售超过上百台轴流泵

A corner of our sales record 部份销量展示

Axial Flow Pumps

1. Use:

The vertical high-temperature molten salt axial flow pump circulates the medium between the tubes in the tubular fixed-bed reactor, so that the reaction temperature is maintained within a certain temperature difference range, and the heat exchange medium acts as a carrier to remove the reaction heat.

2. Features:

2.1 Our company has an impeller computer design program with independent intellectual property rights. The mathematical model and simulation system for establishing the operating parameters of the molten salt axial flow pump are satisfied with the reactor matching requirements. This product uses six technical measures.

2.2 It adopts the integrated structure that can extract the whole impeller and shaft system from the pump casing, which is convenient for installation and maintenance. The optimum clearance is taken between the impeller and the pump body to maintain high pump efficiency. Strict requirements for dimensional tolerances and geometrical tolerances of the pump body and bearing frame are required to ensure accurate coaxiality.

2.3 Combined with the working condition characteristics of the vertical molten salt axial flow pump, the three-point axial pull rod with wedge can be used to adjust the fixing device at the sleeve bracket of the molten salt inner limit bearing seat. The pump shaft is accurately and firmly seated, ensuring smooth operation of the pump, minimizing pump vibration and greatly increasing pump life.

2.4 Adopting rigid shaft, the coaxiality of the shaft system is accurate, which makes the whole machine run smoothly, with low noise and long-term safe operation.

2.5. The limit bearing of the pump in the molten salt is made of special alloy. It is highly abrasion resistant and corrosion resistant.

2.6 The axial spacing of the rolling bearings is chosen reasonably. It is lubricated with high temperature grease. The lower bearing of the pump is cooled by water jacket or air cooled.

2.7 The pump casing and pump body are made of high quality steel that is compatible with the working conditions of the medium.

Technical performance:

1. Pump flow: Q = (500-8000) m3/h

2. Pump head: H = (1.5-6) m

3. Pump revolutions: N = (420 -960) r / min

4. Pump operating temperature: t ≤ 500 °C

5. Motor power: P=(22-240) kw

轴流泵

1. 使用:

立式高温熔盐轴流泵使介质在管式固定床反应器的管道间循环,使反应温度保持在一定温差范围内,热交换介质则带走反应热。

2. 特点:

2.1 我司拥有自主知识产权的叶轮计算机设计程序。其数学模型和模拟系统可满足反应器匹配要求。该模型和系统用于设置熔盐轴流泵的运行参数。本产品引入了六项技术措施。

2.2 本产品采用一体化结构,叶轮和轴系统整体可从泵体外壳拿出,便于安装维护。叶轮与泵体间的间隙保持在最佳水平,保持高的泵效率。泵体和轴承架的尺寸和几何公差有着严格要求,确保同轴度的精准度。

2.3 考虑到立式熔盐轴流泵的工况,可利用带楔块的三点轴向拉杆调节熔盐内限位轴承座套筒支架处的固定装置。泵轴与底座固定牢固精准,可以确保泵的平稳运行,最大限度减少泵的振动,大大延长泵的使用寿命。

2.4 刚性轴保证同轴度的精确性,使整机运行平稳噪音低,可长期安全运行。

2.5 熔盐内的泵机限位轴承采用对腐蚀和磨损抗性极高的特殊合金制成。

2.6 科学设置滚动轴承的轴向间距,采用耐高温润滑脂。泵的下轴承采用水套冷却或自然冷却。

2.7 泵壳和泵体由与介质工作条件相适应的优质钢材制成。

技术性能:

1. 泵流量:500-8000立方米/时

2. 泵头:1.5-6米

3. 泵 转数:420 -960转/分钟

4. 泵运行温度:≤ 500 摄氏度

5. 电机功率:22-240千瓦

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies.